Home > Duplex Steel > Duplex Steel S31803 Pipe

Duplex Steel S31803 Pipes are custom-built from a specific grade of duplex stainless steel, known for its exceptional blend of austenitic and ferritic properties. This unique composition imparts extraordinary strength and corrosion resistance to the pipes, making them an ideal choice for demanding environments encountered in chemical processing, oil and gas operations, and marine engineering. Celebrated for their robustness, elevated tensile strength, and exceptional ability to resist pitting and crevice corrosion, Duplex Steel S31803 Pipes stand as a reliable solution for critical applications exposed to severe conditions.

| Standard | ASTM A790 / ASME SA790 UNS S31803, S32205, S32550, S32750, S32760 |

| Materials | ASTM A815 – UNS S31803 |

| Size | 1/2″NB TO 12 “NB IN |

| Seamless Pipes & Tubes Sizes | 1/2” NB – 8” NB |

| Welded Pipes & Tubes Sizes | 6” NB – 24” NB |

| Thickness | 0.5-45mm |

| Outer Diameter | 6.0-630mm |

| Dimensions | OD(6.0-630)*WT(0.5-45)mm |

| Schedule | SCH20, SCH30, SCH40, STD, SCH80 |

| Type | Welded / Fabricated / Seamless |

| Length | Single Random, Double Random & Cut Length. |

| Ni | Cr | Mo | Mn | Si | C | N | S | P | Fe | |

| MIN | 4.5 | 22.0 | 3.0 | – | – | – | 0.14 | – | – | – |

| MAX | 6.5 | 23.0 | 3.5 | 2.0 | 1.0 | 0.03 | 0.2 | 0.02 | 0.03 | Balance |

S31803 | Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 7.8 g/cm3 | 1350 °C (2460 °F) | Psi – 80000 , MPa – 550 | Psi – 116000 , MPa – 800 | 15 % |

At PipingMart, we take pride in being the largest supplier and manufacturer in the UAE, offering cutting-edge solutions for all your piping needs. With state-of-the-art production plants strategically located in the UAE, we boast a vast inventory of over 25,000 tons of premium-quality materials readily available in stock.

Contact us to get a quick quote for your requirement.

We offer These Duplex Steel S31803 Pipe as per DIN, ISO, JIS or ANSI Standard.

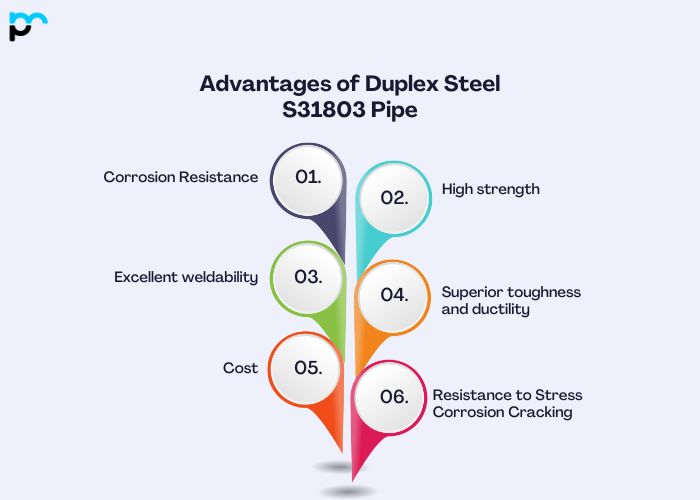

Corrosion resistance: Duplex steel S31803 pipe exhibits excellent corrosion resistance, especially in areas containing chlorides and sulfides. This resistance makes them suitable for various industries, including chemical processing, oil and gas, and marine applications.

High strength: These pipes are stronger than conventional austenitic or ferritic stainless steel. This makes them suitable for applications where strength and durability are important, such as offshore platforms and building components.

Excellent weldability: Duplex steel S31803 pipe has excellent weldability, making it easy to manufacture and assemble. This property is important in projects requiring complex structures and installations.

Superior toughness and ductility: Duplex steel combines the desirable properties of austenitic and ferritic stainless steels for excellent toughness and ductility. This makes it resistant to brittle fracture even at low temperatures, ensuring reliability in harsh working conditions.

Cost: Despite their superior quality, duplex steel S31803 pipes offer a cost advantage over other corrosion-resistant alloys, such as nickel-plated alloys. This makes them attractive options for applications where cost efficiency is a concern.

Resistance to Stress Corrosion Cracking: Duplex steel S31803 pipes exhibit high resistance to stress corrosion cracking (SCC), a common issue in chloride-containing environments. This property ensures the pipe’s reliability and longevity under conditions of greater decay.

Duplex Steel S31803 Pipes applications are as diverse as the industries they serve driven primarily by the aerospace, railway, construction and automotive industries with petrochemical, nuclear, medical, Oil & Gas, Chemical, Pharmaceutical, Food & Beverage, Nuclear, Thermal Power plants, Paper and Pulp, marine and mining, etc.

Chemical applications: These pipes are used in the chemical industry, where chemical stability and high-temperature corrosion resistance are required. They are commonly used in chemical processing plants, tanks, and water out-of-order systems.

Desalination equipment: Duplex steel S31803 pipe is suitable for on-site water desalination from seawater. Their corrosion resistance is important in complex marine environments.

Water Treatment: Duplex steel S31803 pipe is used for water and chemicals due to its resistance to corrosion and corrosion in water treatment plants

Heat Exchanger: Used in heat exchanger systems where corrosion resistance, high efficiency and thermal conductivity are required for efficient heat transfer

Application Requirements: Identify the purpose of the pipe – whether for general use, high-pressure, high-temperature areas, waste products, or any specific industrial application. Duplex steel S31803 pipe is commonly used in oil and gas, chemical processing, desalination and other applications due to its excellent corrosion resistance and mechanical properties.

Materials: Duplex steel S31803 offers a combination of high strength and excellent corrosion resistance. Measure its mechanical properties, such as tensile strength, yield strength, corrosion resistance, and corrosion resistance in various environments, including chloride-containing chemicals.

Size and Dimensions: Based on your project specifications, including thickness, wall thickness, and length, determine the required pipe size and diameter. Ensure that the chosen pipe dimensions conform to industry standards and regulations.

Operating conditions: Check operating conditions, including temperature, pressure, and the nature of the liquid or gas expansion. Duplex steel S31803 pipe is suitable for both high temperatures and high pressures. Still, it is important to ensure that the chosen pipe can withstand specific operating conditions without compromising performance or integrity.

Construction Standards: Verify that duplex steel S31803 pipe meets relevant construction standards and specifications, such as ASTM A790 for seamless welded pipe or ASTM A928 for welded pipe.

Yes, Duplex Steel S31803 Pipes are recyclable. Duplex stainless steel, including grade S31803, is highly recyclable due to its composition of chromium, nickel, and molybdenum. Recycling helps conserve resources, reduces environmental impact, and maintains the material’s value for future use in various industries.

Duplex Steel S31803 Pipes are corrosion-resistant pipes made from a duplex stainless steel grade known for its high strength and excellent corrosion resistance. These pipes are commonly used in various industries such as oil and gas, chemical processing, marine engineering, and desalination due to their durability and resistance to harsh environments.

Industries commonly using Duplex S31803 Steel Pipes include oil and gas, chemical processing, marine engineering, desalination, and pulp and paper. Their corrosion resistance, high strength, and durability make them ideal for applications requiring resistance to aggressive environments, high pressure, and temperature variations.

Yes, Duplex Steel S31803 Pipes can be welded using common welding techniques such as shielded metal arc welding (SMAW), gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and flux-cored arc welding (FCAW). Proper welding procedures and filler materials compatible with duplex stainless steel are essential to maintain its corrosion resistance and mechanical properties.

Call Us: +91 7208967217

Email: sales@pipingmart.ae